All of AMICO Security’s finishing processes involve a zinc layer for superior corrosion protection. Corrosion is an electro-chemical process caused by an electrical potential between two small areas of steel, anodes and cathodes, and an electrolyte. The electrolyte, most often water, starts the corrosion reaction by connecting the anode and with the cathode resulting in iron oxide, which is the brown, flaky rust typically seen on unprotected steel. While a traditional paint layer aims to prevent water from touching the steel, a zinc layer provides a superior cathodic protection replacing the steel anode with a zinc anode resulting in Zinc oxide which forms a protective layer instead of rust.

AMICO Security offers two highly corrosion resistant finishing options:

- Hot-Dip Galvanizing

- AMICOAT™ Powder coating over E-Coating or primer

Hot-Dip Galvanizing Finish

- All components Hot Dipped Galvanized

- Meets ASTM 123 standards

- 10 Year limited Warranty

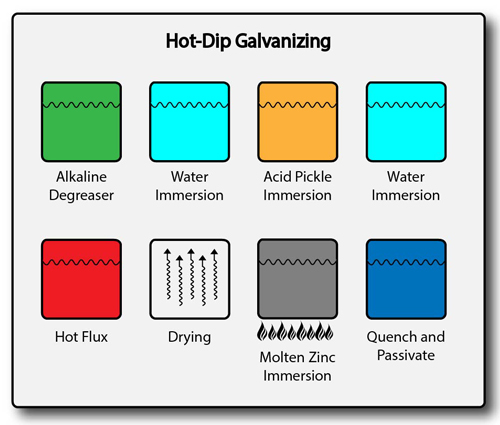

Hot-Dip Galvanizing Process

AMICOAT™ Powder Coating

- Industry Leading AMICOAT™ Powder Coat Coverage over E-Coat or primer base

- AMICOAT™ available in 16 standard colors

- ALL Colors of the RAL Color Chart are available upon request

- 10 Year Limited Warranty

Background image shown in Orna Mesh

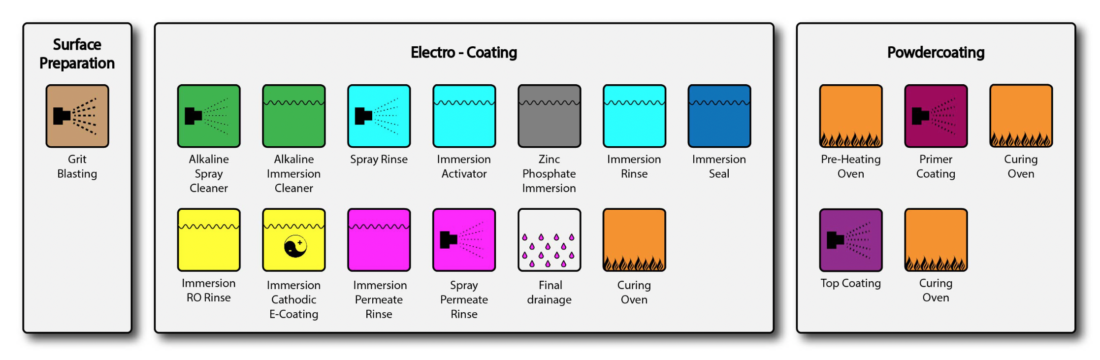

AMICOAT™ Powder coating over e-coat process

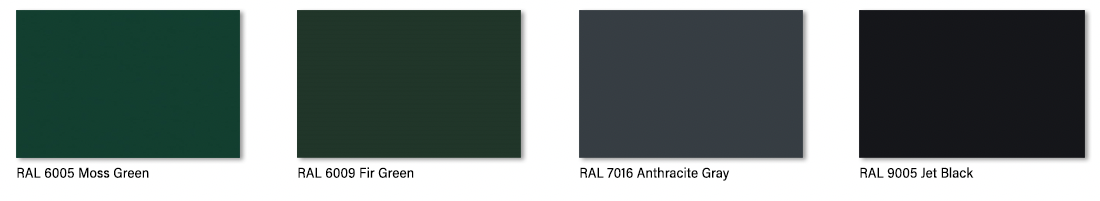

AMICOAT™ Standard Colors for AMIGUARD® 6000 & 7000 Security Meshes

Please note that standard AMICOAT™ colors shown in here are for reference only as they can deviate slightly from the actual colors depending on electronic screen or printing.

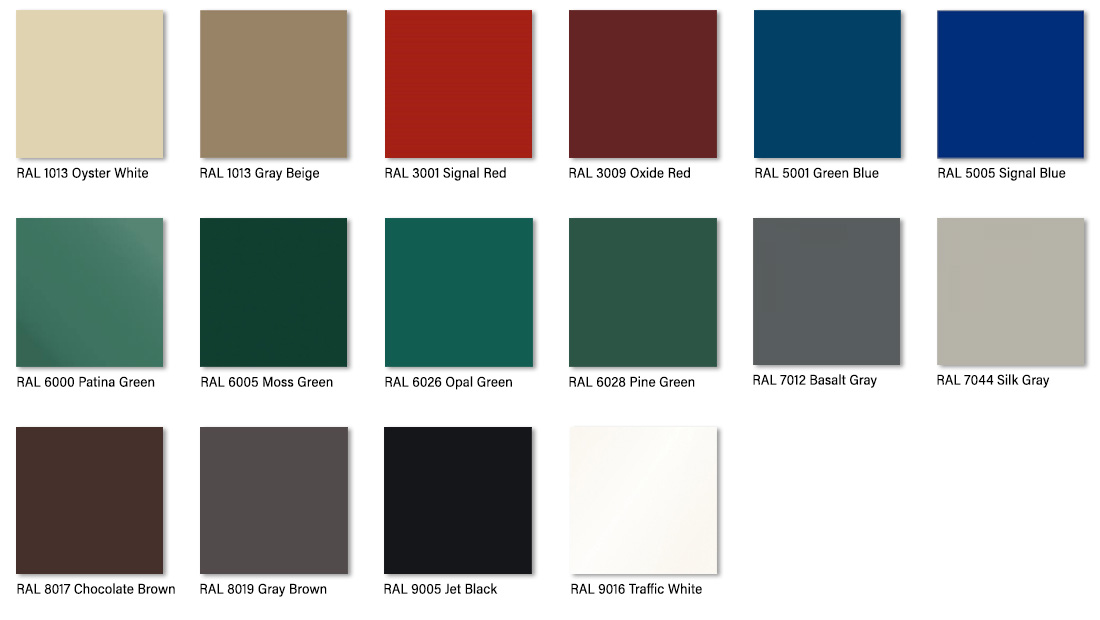

AMICOAT™ Standard Colors for AMIGUARD® 5000 Wire Meshes

Please note that standard AMICOAT™ colors shown in here are for reference only as they can deviate slightly from the actual colors depending on electronic screen or printing.